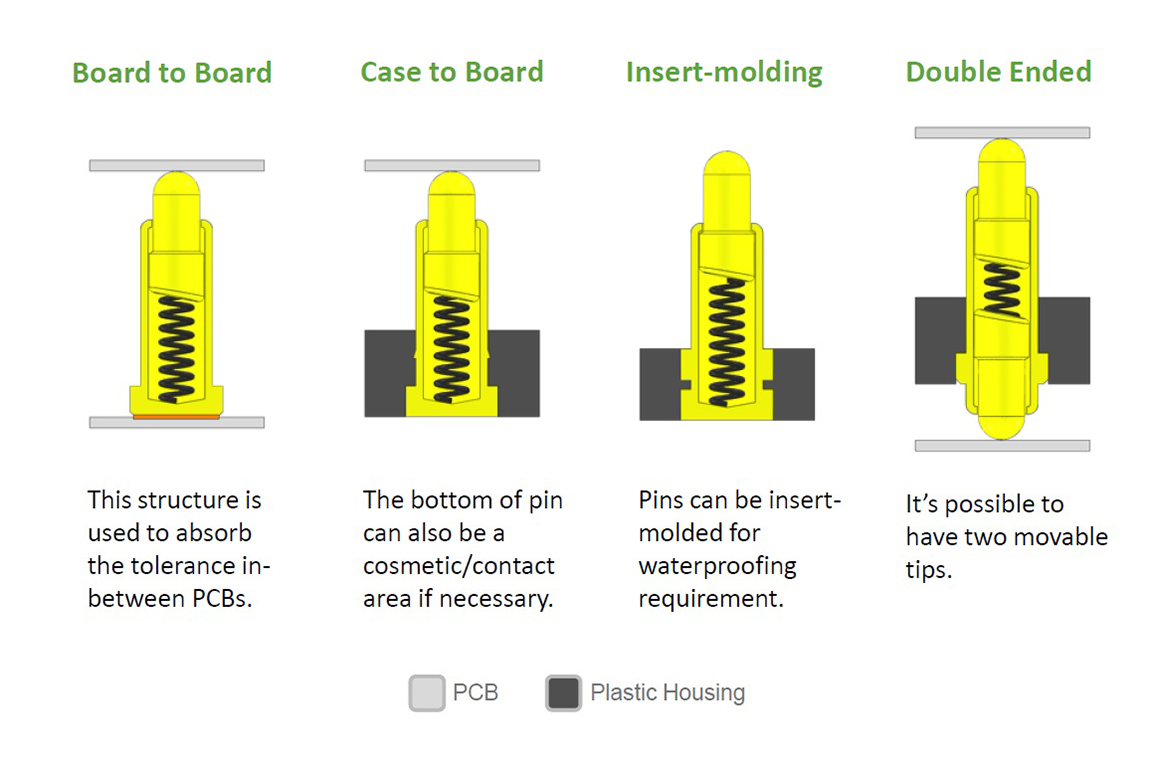

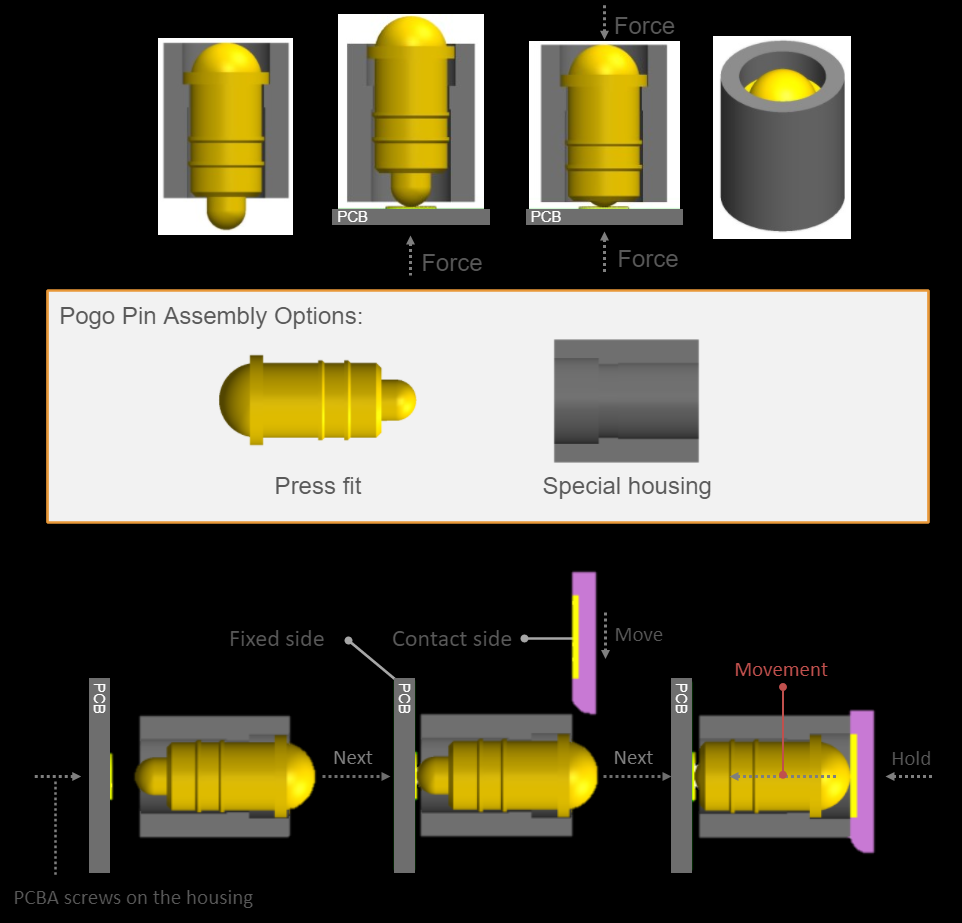

A Pogo pin is a precision connector used in electronic products for charging.

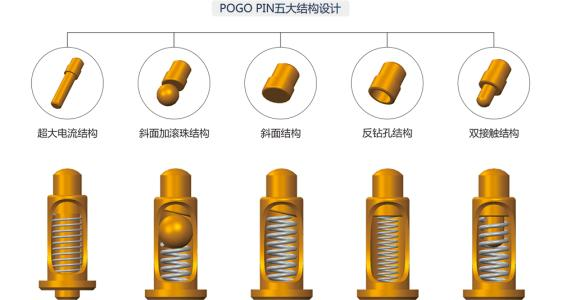

It is widely used in semiconductor equipment for connection. Different appearances are depending on the application, but there is a precision spring structure inside the pogo pin as a whole. The surface of this product is generally gold-plated, and the spring should also be gold-plated when the process is required.

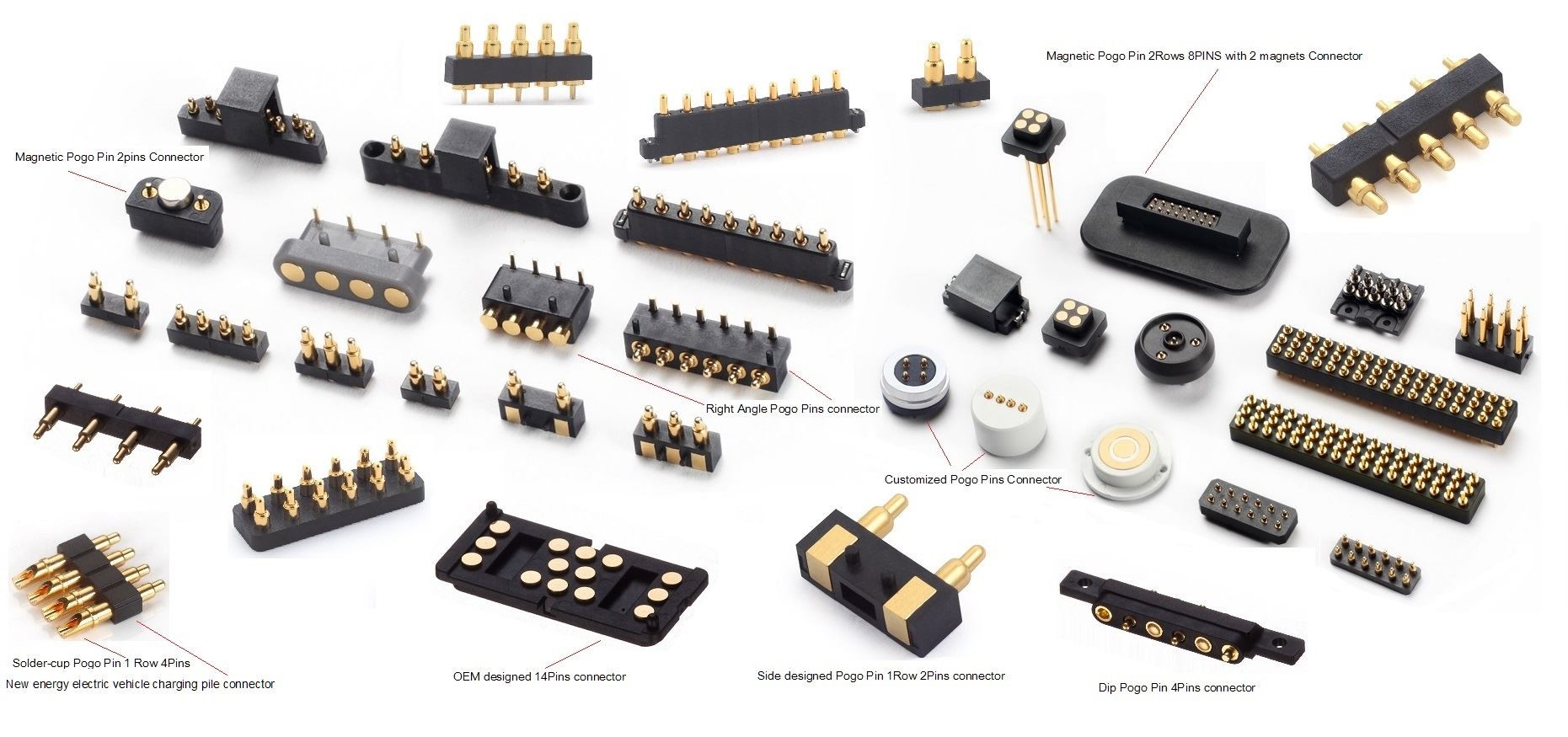

The scope of use of pogo pins is very wide, and it is used in many places:

Aviation, aerospace, military communications, and military electronics. Automotive, in-vehicle navigation, test, and measurement equipment. Medical equipment, wireless equipment, data communication equipment, telecommunications equipment, automation, and industrial equipment. Consumer electronics (printers, mobile phones, computers, cameras, audio-visual equipment, PDAs, Bluetooth headsets, etc.). Smart wearable devices, smart positioning devices, children's smart bracelets, smart watches, smart robots, drones, wearable mobile phones, Bluetooth headsets, etc., data cables, charging cables, magnetic suction line board line end connectors.

What is the process of making pogo pins?

Pogo pin processing: use the most advanced and confidential machine tools to process pogo pins, and the processed parts must meet quality standards.

Pogo pin electroplating: This is also an essential part, of ensuring that the gold plating layer in the hole is good, with no blackening, different colors, and poor plating.

Pogo pin electroplating: This is also an essential part, to ensure that the gold plating layer in the hole is good, with no blackening, different colors, and poor plating.

Pogo pin quality inspection: After the processing is completed, the quality department will check each pogo pin to see if there is any difference in appearance and whether the spring has elasticity, etc.

Batch sampling inspection and shipment: Before shipment, a batch of products will be selected from the qualified products for review, and they will be shipped only after there is no problem with the inspection.